Neoxalin and its pros and cons

Schärer & Schläpfer AG has been producing various phosphoric acid esters for over 40 years. They are marketed under the name neoxaline. The range of established standard products is constantly being expanded with new types – for some time now with increased effort. This is because neoxaline is an effective anti-corrosion agent. In Part 2, we highlight the advantages and disadvantages of neoxaline in comparison with common rust inhibitors.

Toxicity – a big problem with conventional corrosion protection

In the first blog about neoxaline, we learned about the tremendous damage rust causes. That is why a lot of money is invested to protect steel from corrosion. However, there is a big problem with conventional corrosion protection: toxicity. Chromate, for example, the salts of chromic acid, are considered the best-known corrosion protection. However, there are only a few areas where chromate may still be used for surface treatment. The reason: Chromic acid and chromates (e.g., potassium dichromate) are among the substances classified as substances of very high concern in the REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals). This is because all chromates – as well as other chromium (VI) compounds (with the exception of the water-insoluble barium chromate) – are highly toxic, hazardous to water and carcinogenic. "Because other common rust inhibitors such as sodium borate or nitrite are also harmful to the environment and are to be replaced with harmless agents, alternatives are urgently being sought," says Manuel Blunier, Head of Sales & Marketing at Schärer & Schläpfer AG.

"Because other common rust inhibitors such as sodium borate or nitrite are also harmful to the environment and are to be replaced with harmless agents, alternatives are urgently being sought,"

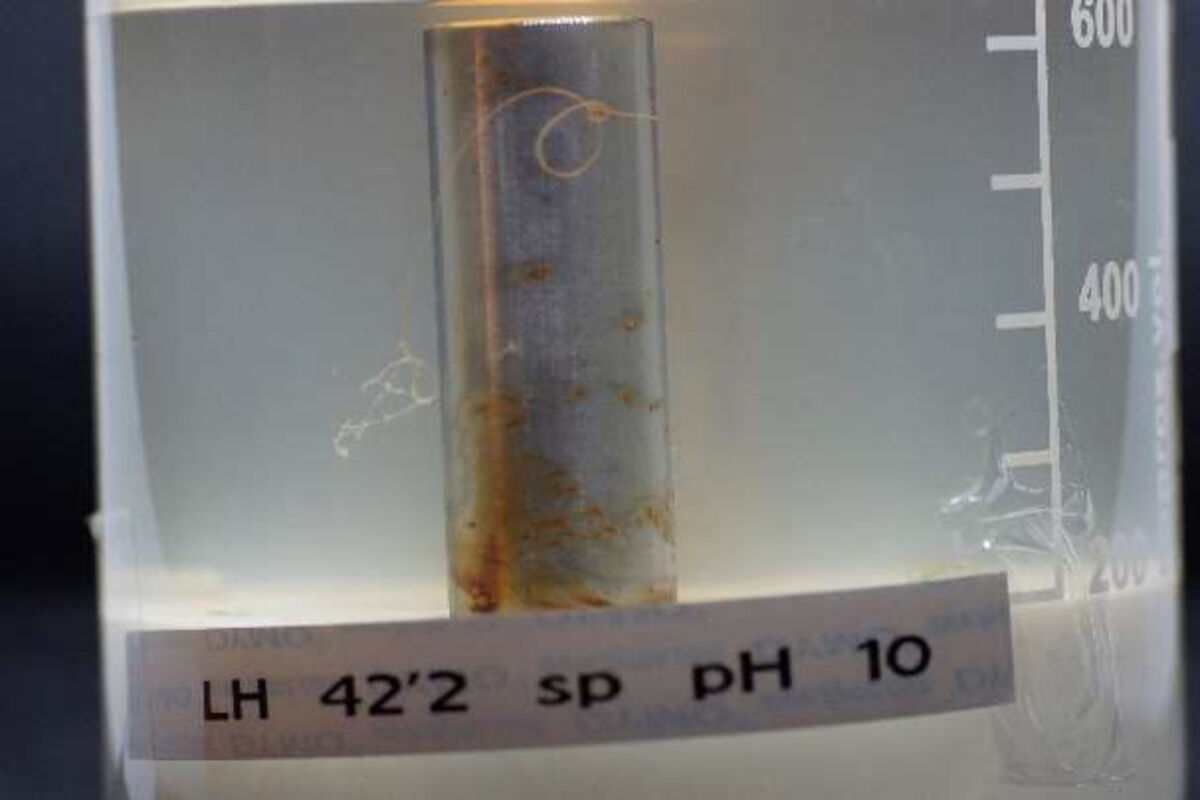

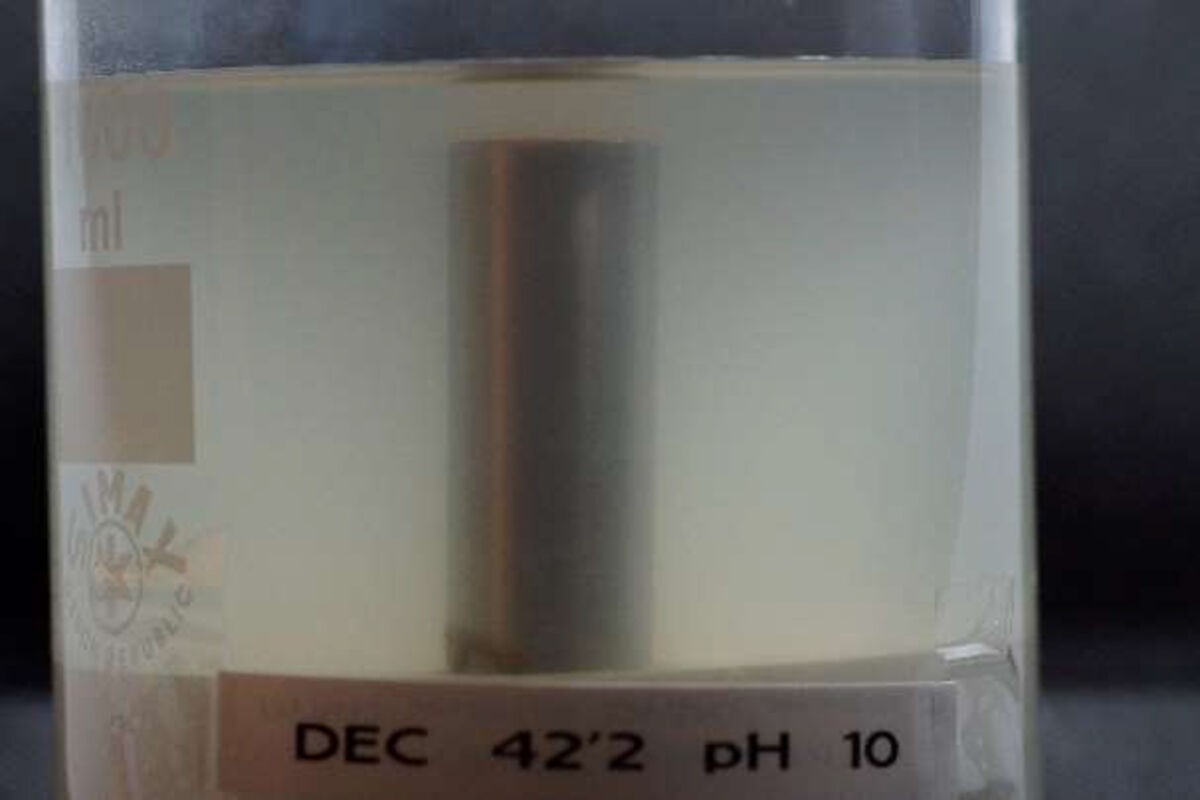

Some neoxaline from Schärer & Schläpfer AG have great potential in this respect, Manuel Blunier is convinced. This is confirmed by the corrosion tests carried out by Dr. Wolfgang Rauh. He has examined the products neoxaline DEC 42, LH42 and LH 42 spec. His conclusion: "All products tested resulted in very low mass removal even at extremely low concentrations." The products were tested over a period of seven days at pH values of 5, 7 and 10 on steel 100 Cr 6 GKZ, a high-strength low-alloy material very frequently used in industry. Criteria for assessing the effectiveness of the protective agents were the mass loss of the test specimens and the condition of their surfaces with respect to the occurrence of pitting corrosion or pitting. The pictures are impressive and clearly show that the neoxaline used forms a superficial protective layer on the steel and reliably prevents rust formation and pitting.

Pictures of the corrosion investigations

Designation of the sample: DEC 42’2

Designation of the sample: DEC 42’3

Designation of the sample: LH 42’2

Designation of the sample: LH 42´3

Designation of the sample: DEC 42’2

Designation of the sample: DEC 42’3

Neoxalin – promising corrosion and wear protection

Neoxaline DEC 42 proved to be particularly effective, with a very good protective effect even at a significantly lower concentration (0.01%). "It's our super corrosion protection," Manuel Blunier is pleased to say. With neoxaline LH 42, on the other hand, reduced foam formation was noticed, he said. "This is an important aspect, since foam is not desirable in some applications, such as cooling lubricants." In many applications, however, foam is quite desirable, for example in bicycle frame or rim cleaners. In addition to corrosion protection, the neoxalines also offer a certain degree of wear protection, especially in the acidic range, which also makes them wonderful additives in cutting oils, for example.

One disadvantage of the three products examined by Wolfgang Rauh is their relatively low solubility in water. "Depending on the area of application, they therefore required a solubilizer," says Rauh. In combination with a suitable surfactant, however, they are very valid, environmentally compatible corrosion protection solutions. For glycol-based cooling brines, for example, the products Neoxalin DEC 42, Neoxalin LH 42 and Neoxalin LH 42 spez could also be used without solubilizers, as they are readily soluble in these media. Most of the products from the neoxaline family, however, are readily soluble in water, emphasizes Manuel Blunier. But one thing is already clear: The phosphoric acid esters from Schärer & Schläpfer promise a lot in terms of corrosion and wear protection. But not only in this respect. In the next part, we will explore the full potential of the neoxaline product range.